What if your boldest idea could become a reality by tomorrow?

What if your startup could deliver custom solutions at scale, with less waste and more agility than ever before?

This isn’t science fiction-it’s the new normal, thanks to digital fabrication.

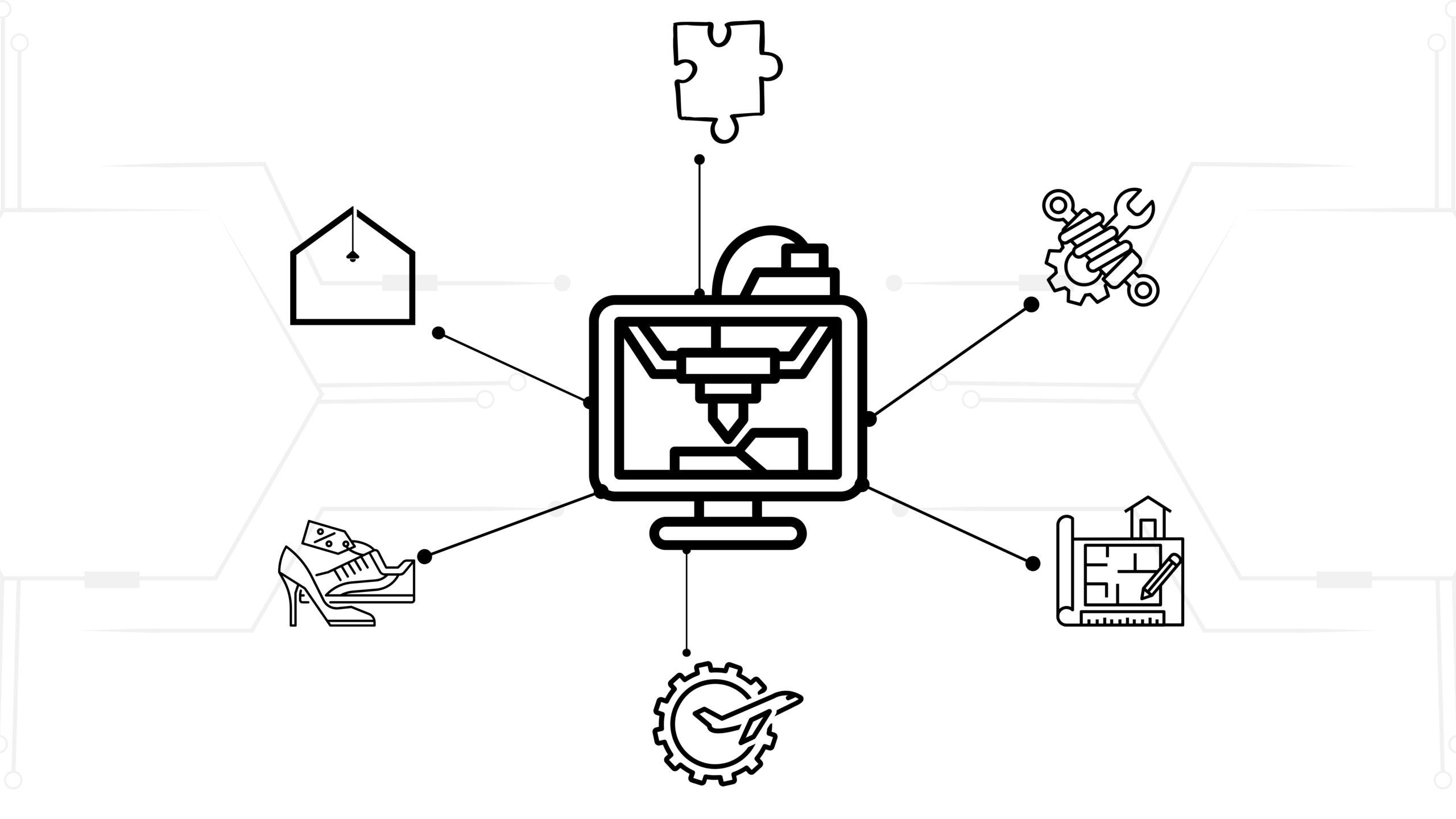

Digital fabrication has been quietly transforming the way we design, prototype, and manufacture for more than a decade. Today, its impact is accelerating, driven by more accessible tools, smarter software, and growing demand for speed, customization, and sustainability.

By harnessing computer-controlled machines such as 3D printers, CNC routers, and laser cutters, businesses of all sizes can now turn digital designs into physical products with unprecedented speed, precision, and flexibility.

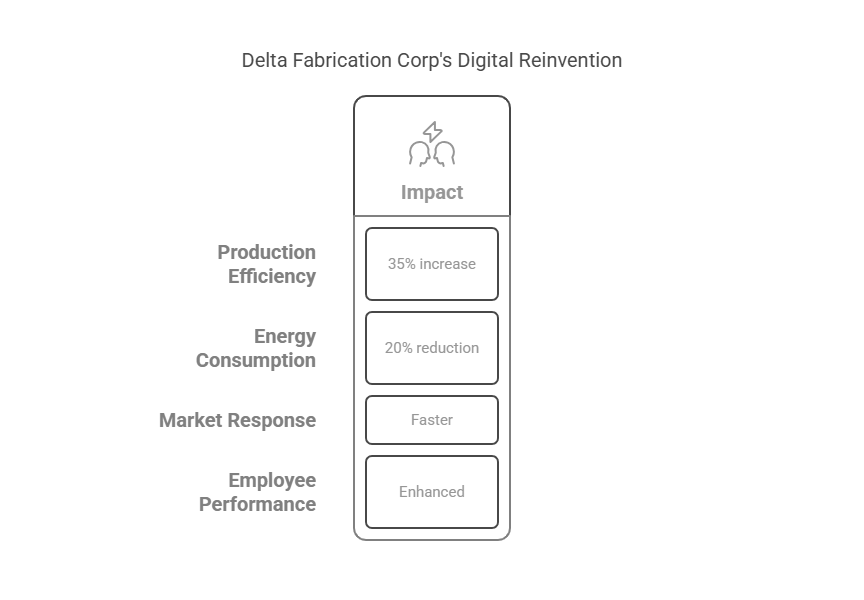

Delta Fabrication Corp, a forward-thinking manufacturing company, faced rising costs and outdated manual workflows. To modernize, they adopted a digital fabrication strategy that combined 3D printing for faster prototyping, smart sensors for real-time production monitoring, and augmented reality to enhance employee training and diagnostics.

This transformation allowed them to replace slow, multi-step prototyping with quick, in-house iterations, identify bottlenecks through live production data, and reduce onboarding time by guiding new employees with AR-supported processes.

Delta’s shift shows how manufacturers can integrate digital fabrication into existing operations to boost agility and deliver tailored solutions without requiring a complete overhaul.

Digital fabrication is no longer limited to manufacturers. It is now empowering startups, architects, and designers to create and scale faster than ever. Platforms like Xometry and Carbon offer on demand production, while brands like Adidas use 3D printing for cutting edge products like the Futurecraft 4D. But speed is just the beginning. The real shift lies in real time customization. Tools like Shapediver and advanced online configurators allow end users to interact directly with digital models, adjusting materials, dimensions, and features before anything is produced. It is not just production, it is co-creation.

This wave of interactive fabrication is democratizing innovation, enabling small teams to deliver tailored, made to order solutions that once required enterprise scale resources. The barriers are falling and customization is leading the charge.

Digital fabrication is more than a trend, it’s a paradigm shift. For startups and innovators, it means faster prototyping, scalable customization, streamlined workflows, and sustainable growth.

The future belongs to those who embrace this digital revolution, are you ready to lead the way?

Ready to unlock the power of digital fabrication for your business? Let’s build the future-together.