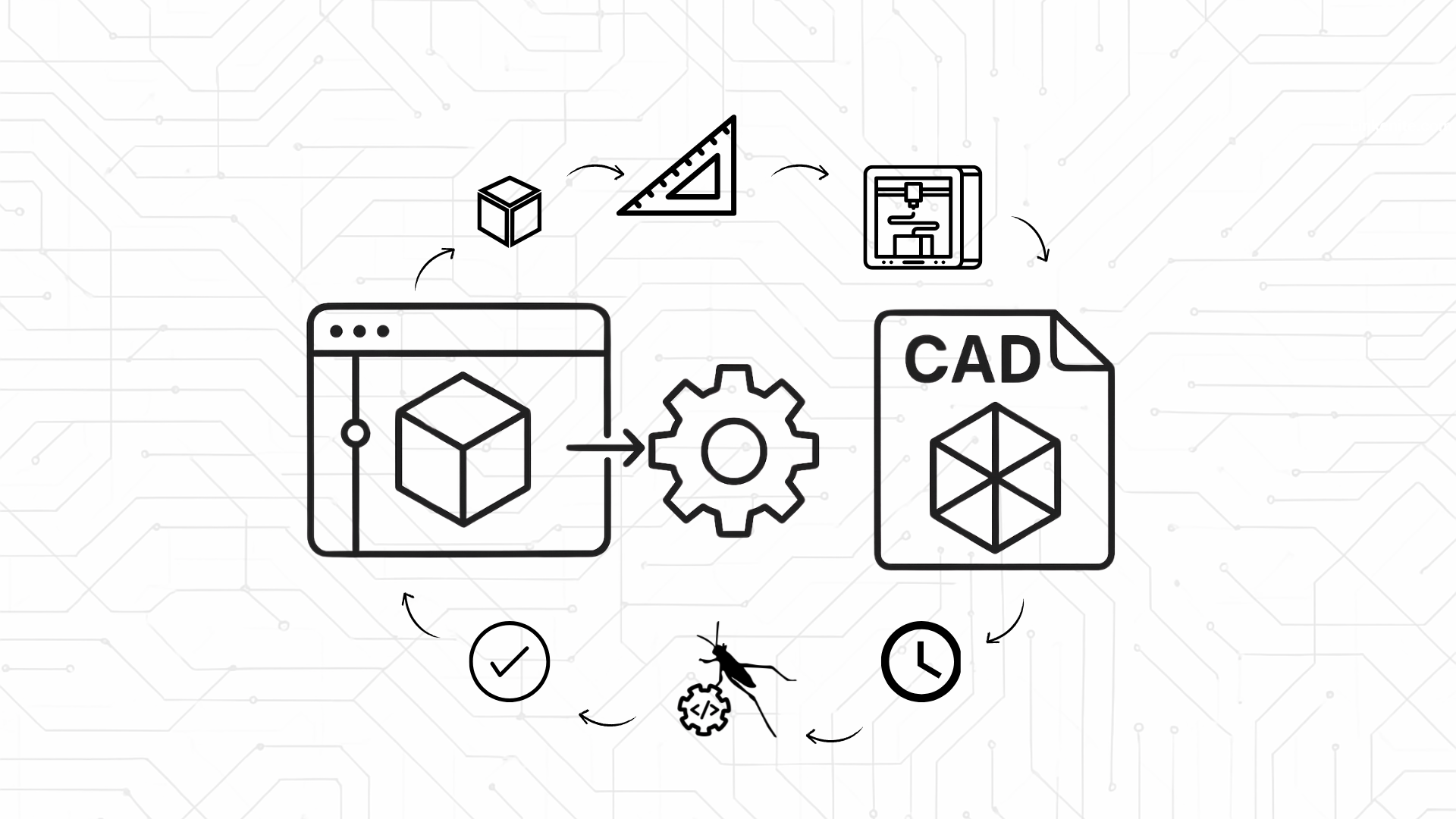

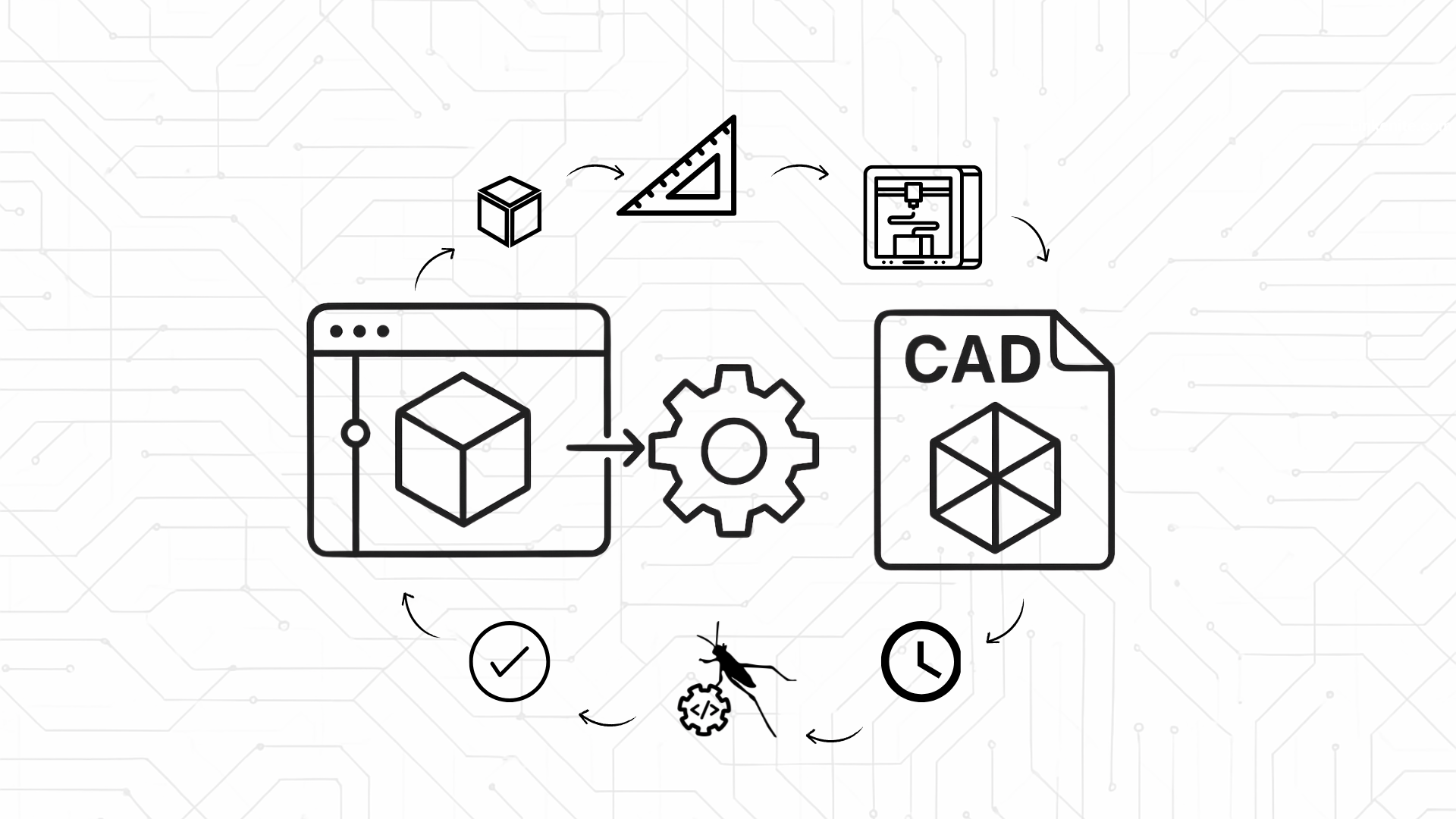

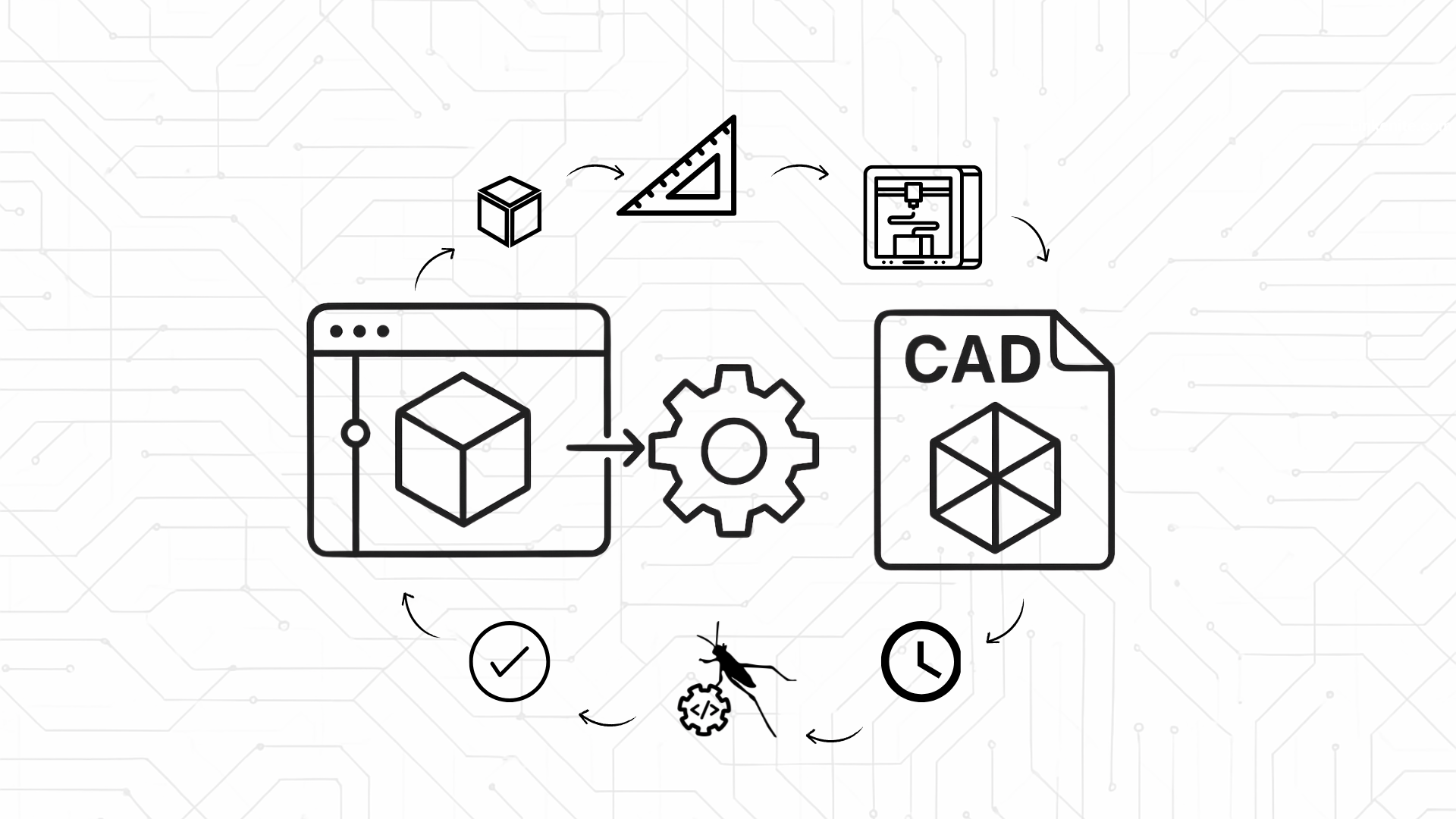

Imagine a customer adjusting a slider on your website. The product updates instantly. A chair becomes shorter, a pattern shifts, a custom engraving appears. But behind that simple click, something powerful is happening.

The system is generating production-ready files, calculating material requirements, and preparing everything for manufacturing automatically. No back and forth. No manual work. Just a seamless flow from customer input to build-ready output.

ShapeDiver uses parametric design, where customer choices algorithmically adjust the final output, similar to how changing an ingredient alters a baking recipe.

Why does this matter?

“Customers aren’t just buying, they’re co-designing. Yet every tweak stays production-viable,” notes a WAZP engineer using ShapeDiver to 3D print custom parts.

Here’s what happens milliseconds after a customer clicks “Update Design”:

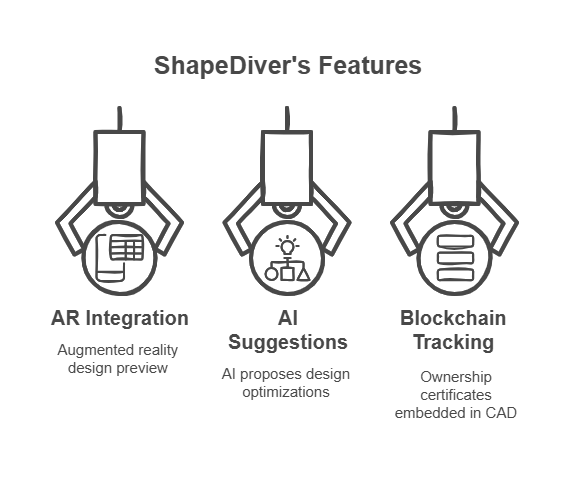

Recent advancements are pushing boundaries:

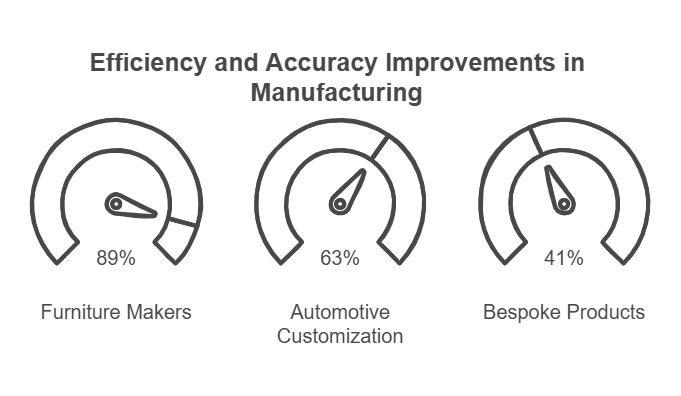

The Numbers Don’t Lie:

Companies using ShapeDiver report 73% less wasted material & 58% of manufacturers now prioritize “configurator-to-factory” tools over traditional CAD.

Meet Maria, a small-business owner crafting custom lamps. Before ShapeDiver:

After ShapeDiver:

“It’s like having a 24/7 design engineer and sales team,” she says.

ShapeDiver isn’t just changing how products are made, it’s redefining who gets to make them. From garage startups to Fortune 500s, the playing field is leveling.

Ready to Join?

The next time a customer clicks “buy,” remember: Behind that button lies a revolution, stitch by digital stitch, transforming imagination into inventory.