The Next Wave of Geometry Rationalization in Sustainable Architecture

Can Complex Geometry Ever Be Truly Sustainable?

Why do so many of the buildings that capture our imagination end up wasting material, time, and energy during fabrication? The answer is rarely about the vision itself. It’s usually about the geometry, or more specifically, how that geometry is rationalized from a digital model to built form.

This is where the next wave of sustainable architecture is taking shape. As parametric design and digital fabrication mature, geometry rationalization is moving from a niche technical step to the core of how projects achieve sustainability and profitability.

The State of Play Today

Sustainable architecture has evolved far beyond recycled materials and energy-efficient systems. Yet one stubborn barrier remains: aligning design ambition with fabrication reality.

- Many models require extensive rework before they can be manufactured.

- Double-curved or freeform surfaces often demand costly custom tooling.

- Iterations are slow, reducing freedom to test lower-impact options.

In short, sustainability goals are often compromised by inefficient workflows. The next wave of rationalization aims to close this gap, ensuring that computational models are not only visionary but also resource-efficient, fabrication-ready, and commercially viable.

How the Next Wave Will Reshape Design

1. Parametric Workflows That Anticipate Fabrication

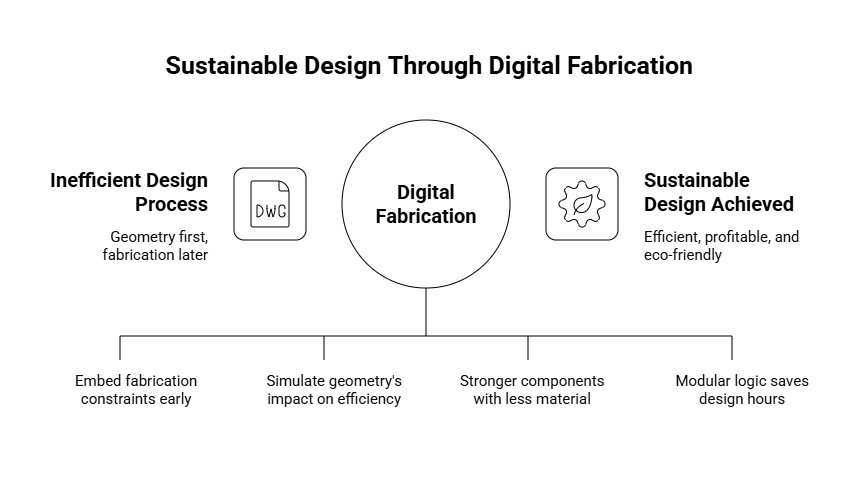

In the past, design teams created geometry first and considered fabrication later. That often led to striking designs that were impractical to build.

Today, Rhino 3D fabrication and Grasshopper scripts can embed fabrication constraints into the design phase. Façade systems, for instance, can be rationalized into flat or singly curved panels without losing architectural intent.

Think of it as designing with the workshop in mind, every change in the digital model immediately reflects how it can be produced. This reduces clashes, speeds up timelines, and minimizes waste.

2. Sustainable Material Strategies Through Geometry

Sustainability isn’t just about what material you choose, but how you shape it. Complex geometries often create excessive offcuts, scaffolding, or reinforcement. With digital prototyping in Rhino, teams can simulate how geometry choices impact material efficiency.

Imagine rationalizing a façade surface so panels align with standard sheet sizes. A single design decision could cut aluminum waste nearly in half. Or consider a timber roof: parametric tools allow testing of multiple structural layouts, selecting the option that uses fewer beams without compromising strength.

These aren’t theoretical gains, they directly influence budgets, delivery, and environmental footprint.

3. Additive Manufacturing and Non-Planar Slicing

Additive manufacturing has entered architecture but remains underused. Most 3D printing still relies on flat layers, which weakens structures and wastes support material.

The next wave introduces non-planar slicing, where layers follow curves rather than stacking flat. This approach produces stronger, smoother components with less material. Picture a concrete beam printed along its natural stress lines, requiring less reinforcement yet performing better.

By linking computational design fabrication tools with new slicing strategies, sustainability gains become built into the workflow.

4. Profitability Through Reusable Workflows

For sustainability to thrive, it must also make financial sense. One reason firms hesitate to adopt digital fabrication is the perceived cost. But reusable parametric workflows flip that calculation.

A firm might build a rationalization script for modular façade panels on one project, then adapt it across cultural centers, transit hubs, or housing. Instead of reinventing processes, the same logic is applied, saving design hours and improving outcomes each time.

Efficiency, sustainability, and profitability converge when workflows are modular and transferable.

Why Training Makes the Difference

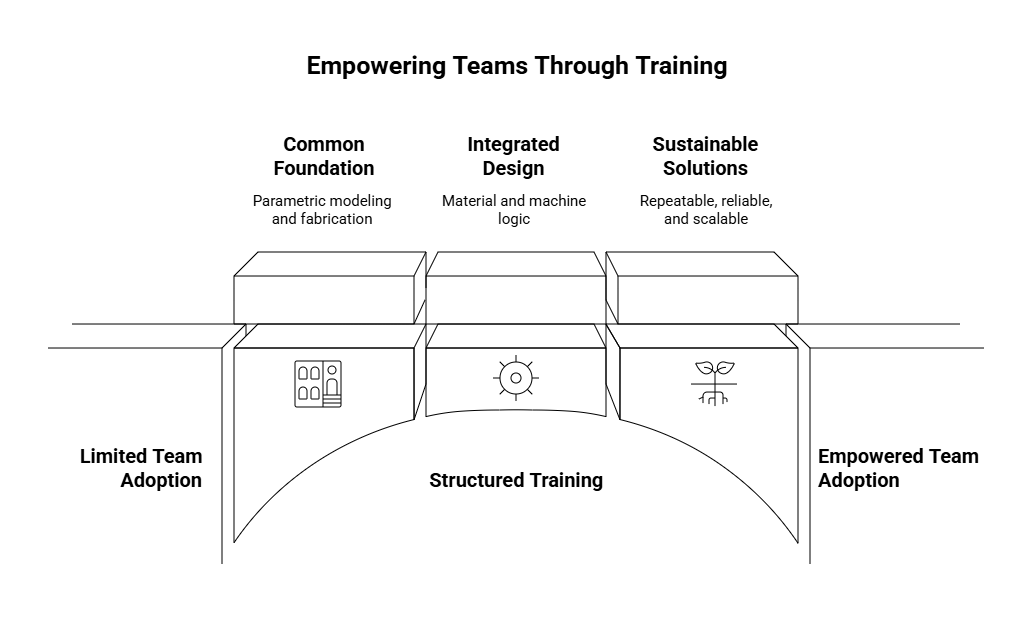

The tools exist. The challenge is adoption. Many teams still rely on one or two “computational specialists,” while others experiment through trial and error. Without structured training:

- Workflows remain fragile and inconsistent.

- Promising strategies are abandoned as “too complex.”

- Knowledge stays siloed instead of spreading across the team.

With the right training:

- Teams share a common foundation in parametric modeling and fabrication.

- Geometry is designed with material and machine logic in mind from the start.

- Sustainable solutions become repeatable, reliable, and scalable.

At Borg Markkula, our team-focused Rhino and Grasshopper courses are built around this exact challenge. We don’t teach abstract software tricks, we guide teams through real project workflows: façade rationalization, modular fabrication, additive manufacturing. The result is knowledge applied, not just learned.

A Future Defined by Geometry

The next decade of sustainable architecture won’t be remembered for the materials we discovered, but for how intelligently we used them. Geometry rationalization is becoming the hinge between creativity and responsibility the key to designs that are visionary yet buildable, bold yet efficient.

Teams that master this shift will not only reduce waste but also open new design freedoms, confident that every curve, surface, and panel has a clear path from screen to site.

And the firms that invest in equipping their teams with this knowledge today will lead tomorrow’s industry.

A Collaborative Next Step

Sustainability isn’t just about ambition. It’s about ensuring ideas translate into practical, efficient, and environmentally responsible realities.

At Borg Markkula, we help design and engineering teams bridge the gap between concept and fabrication. Our training programs in parametric design and digital fabrication build the skills and confidence teams need to thrive in this next wave.

If your projects struggle to align creative vision with sustainable delivery, let’s talk. Even a short conversation can uncover how small shifts in workflow could cut rework, reduce waste, and sharpen your competitive edge.

👉 Book a free 30-minute call with us to explore how your team could lead the next wave of sustainable design.

https://calendly.com/kane-borgmarkkula/30min