Design Freedom Meets Manufacturing Reality

What if anyone, not just trained engineers, could design a product that’s production ready in minutes?

This isn’t science fiction. Manufacturing aware generative AI is lowering traditional design barriers, making it possible for more people to move from concept to factory without years of technical training.

The shift isn’t just about speed. It’s about participation. As cloud platforms, AI algorithms, and on demand manufacturing converge, the line between designer and maker is dissolving. The real power lies in linking creativity with the practical realities of fabrication.

The State of Democratized Design

For decades, professional grade design tools were locked behind steep learning curves and expensive licenses. Even with CAD and parametric modeling, designs did not necessarily resolve using embedded manufacturing knowledge, and they rarely tested fabrication limitations as part of the design process. As a result, strong ideas could still fail before reaching production. Generative AI is narrowing that gap by embedding manufacturing knowledge into the design phase. Instead of manually redrawing, testing, and troubleshooting, designers can now:

- Generate multiple viable options based on goals and constraints

- Integrate real-world production limits from the start

- Optimize geometry, materials, and performance for the intended manufacturing method

This isn’t about replacing the designer. It’s about freeing them to focus on decisions that matter while AI handles the heavy lifting of iteration and optimization.

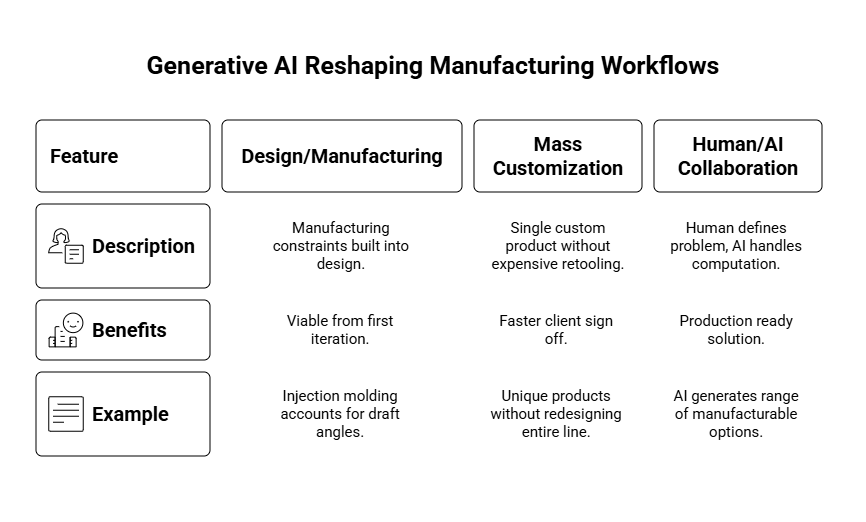

Three Ways Generative AI Is Reshaping Manufacturing Workflows

1. Design and Manufacturing Speak the Same Language

Instead of producing designs that look great on screen but fail in production, manufacturing aware platforms build process constraints directly into the model.

Example: A design intended for injection molding will automatically account for draft angles, parting lines, and wall thickness so it’s viable from the first iteration.

2. Mass Customization Without Mass Production Barriers

Cloud based generative design paired with on demand manufacturing means a single, custom product can be designed, optimized, and produced without expensive retooling.

Small and mid sized businesses can now:

- Create unique products without redesigning the entire line

- Use automated feedback and instant quoting for faster client sign off

- Deliver variations at industrial level efficiency

3. Human AI Collaboration as a Creative Accelerator

The best results come when human expertise defines the problem and AI handles the computational work.

Example workflow:

- Define performance targets, aesthetic direction, and material preferences

- AI generates a range of manufacturable options

- Refine and combine ideas into a final, production ready solution

Beyond the Design Phase: The Connected Workflow

The real leap is in linking design to every other stage of production.

We’re seeing generative design tools connect directly with:

- Digital twins for real time performance simulation

- Supply chain data for cost and lead time awareness

- CAM and CNC programming for direct to machine fabrication

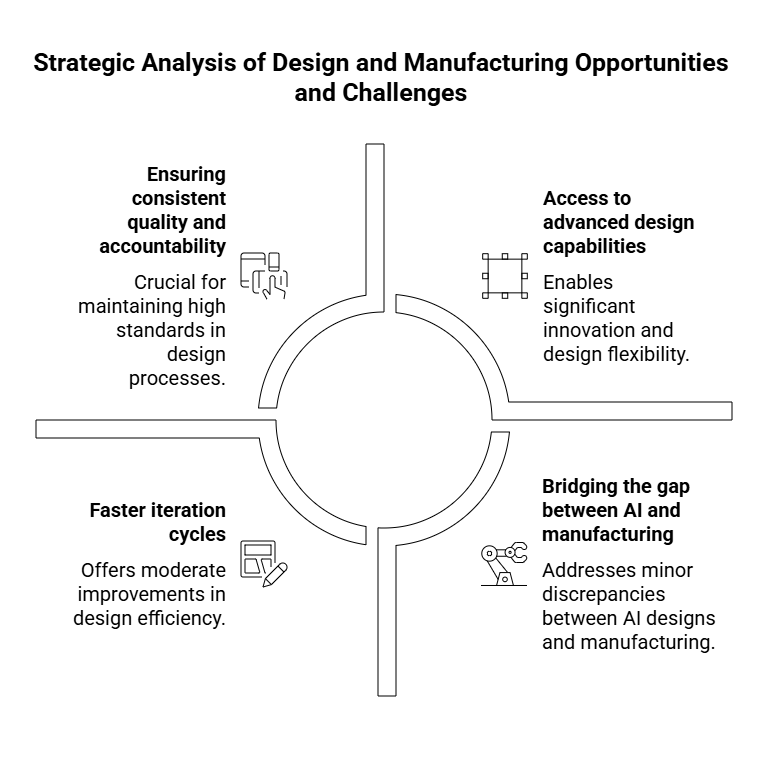

Opportunities and Challenges

Opportunities

These are strong already but can be tightened slightly to feel more like direct benefits rather than generic statements:

- Access to advanced design capabilities for teams beyond traditional specialists

- Faster iteration cycles with reduced prototyping costs

- Stronger alignment between design intent and manufacturing outcomes

Challenges

This is where the real tweaks are needed to reflect concern about “quality control concerns” and to make them more precise:

- Ensuring consistent quality and accountability as more non-engineers enter the design space (instead of “Maintaining quality control”)

- Bridging the gap between AI-optimized designs and current manufacturing capabilities (instead of “limitations,” which sounds overly negative)

- Redefining roles and responsibilities in an AI-augmented workflow (clearer than just “Redefining professional roles”)

Why This Matters for the Future of Manufacturing

Democratized, manufacturing aware generative design is more than a trend. It’s a shift in how products are conceived and made.

In the near future, we’ll see:

- Voice or text based prompts creating fully manufacturable designs

- Predictive systems that solve manufacturing issues before they occur

- Real time collaboration platforms where designers, engineers, and fabricators work in sync from anywhere in the world

Our Take at Borg Markkula

For design teams, the opportunity isn’t just to adopt new tools. It’s to integrate them into workflows that already account for manufacturing constraints. That’s where the real ROI appears: fewer redesigns, faster cycles, and products that are right the first time.

We work with teams to bridge creativity and manufacturing logic, ensuring generative design is providing value to the design process by improving alignment with design goals and KPIs, while also reducing the cost of ‘trying something out.’ clear, outcome-driven, ties directly to measurable impact.

The barrier between idea and product is disappearing.

The real question now is: What should we make next, and how quickly can we get it into the real world?