Folding the Future of Manufacturing

How Borg Markkula’s Computational Design Expertise Helped Power STILFOLD’s Platform

Breakthroughs in manufacturing often come not from faster machines or stronger materials but from rethinking geometry itself.

That’s exactly what happened when STILFOLD began developing its platform and in the early stages, Borg Markkula contributed as a development partner focused specifically on computational design software.

BM provided computational geometry expertise that helped prototype STILWARE, the parametric design engine that transforms CAD assemblies into foldable, flat-sheet structures. While Borg Markkula’s contribution was concentrated in this initial phase, STILFOLD has since taken full ownership, scaling and industrializing the software as part of its proprietary IP.

Today, STILWARE sits at the core of the STILFOLD platform, alongside STILTOOL and STILWORKS. Together, these tools enable industries to cut component counts, reduce material waste, and move from concept to production with speed and precision.

In manufacturing, some of the most exciting breakthroughs don’t come from new raw materials or faster machines. They come from rethinking the geometry itself, the way a design is conceived, optimized, and made real.

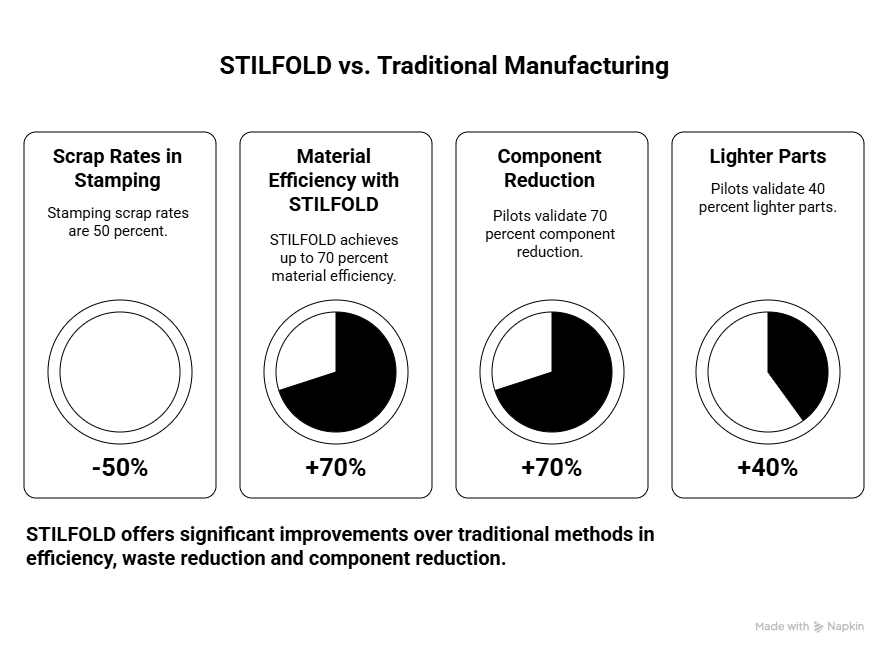

Traditional workflows mean high CapEx tooling, 50% scrap rates in stamping, dozens of welded components, and assemblies that end up heavier than efficiency goals allow. Even a small design change can trigger hours or days of costly rework.

Unlike traditional bending, which relies on straight creases, STILFOLD’s proprietary curve-folding method maps complex, organic lines that transform flat sheets into strong structures.

This breakthrough is not just theory. It is protected IP, developed and industrialized by STILFOLD, and now being scaled across multiple industries.

This is the reality for many engineering and manufacturing teams. It is also exactly the challenge solved by the STILFOLD platform, powered by STILWARE, the computational design software developed with Borg Markkula, which delivers up to 70% material efficiency, 70% component reduction, and assemblies up to 40% lighter.

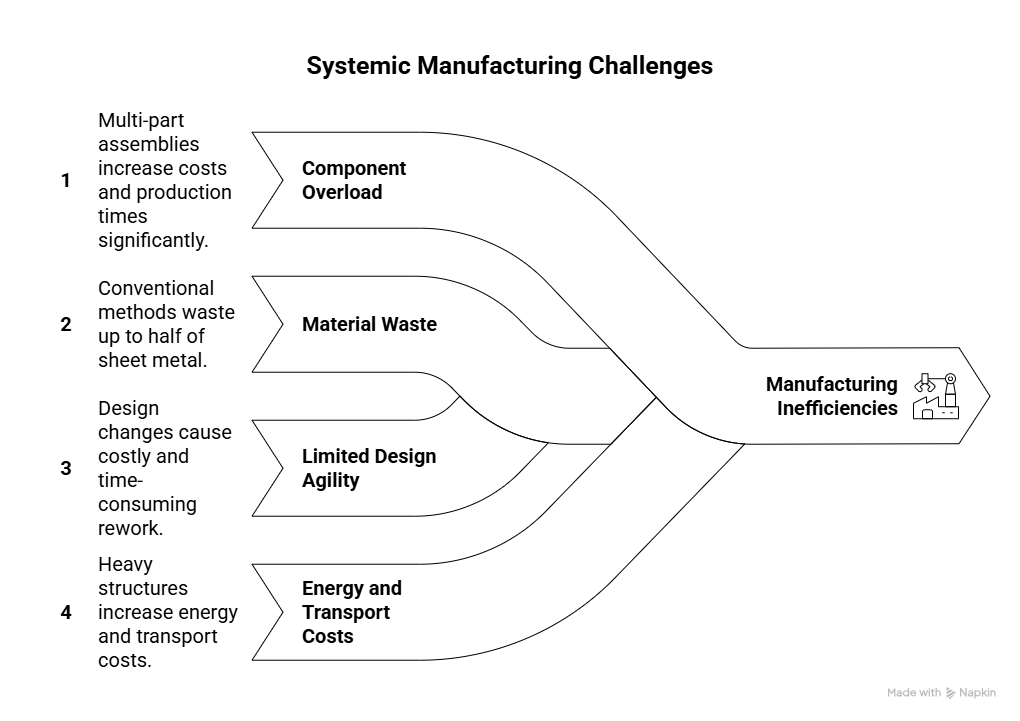

The Pain Points of Traditional Manufacturing Workflows

Even the most advanced manufacturing facilities face inefficiencies that run deeper than surface-level bottlenecks. Traditional approaches to sheet metal and complex geometries expose four systemic challenges:

Component Overload

Multi-part assemblies multiply costs, extend production times, and increase the risk of failure across every joint.

Material Waste

Conventional stamping and cutting can waste up to half of every sheet, locking inefficiency into the process from the start.

Limited Design Agility

Every adjustment ripples through drawings and tool paths, turning small design changes into costly, time-consuming rework.

Energy and Transport Costs

Heavy, multi-part structures consume more energy to fabricate and more resources to ship, undermining sustainability and efficiency goals.

These inefficiencies have been so common for so long that many teams simply see them as “the way it’s done.” But parametric workflows prove it doesn’t have to be this way.

Curve Folding: Where Mathematics Meets Manufacturing

At its core, curve folding applies geometric algorithms, similar to those in paper origami to industrial-scale materials.

But unlike paper folding, which uses straight creases, curve folding algorithms map complex, curved lines that create fluid, organic forms from flat sheets.

Here’s how Borg Markkula’s custom parametric design solutions helped bring the STILFOLD concept into production:

- Creation of computational design toolkit to design for foldability using curve folded geometry.

- These designs are parametric, meaning key dimensions and relationships are driven by adjustable parameters.

- Robotic fabrication arms then fold sheet material along these curved lines with precise, repeatable movements.

The result? Fewer components, optimized material use, and designs that adapt instantly to changes.

Before & After: How Stilfold is transforming manufacturing with curve folding

Status Quo vs Stilfold

- High CapEx trolling (presses, molds) is the elephant in the room vs STILTOOL robotic folding.

- 50% scrap rates in stamping vs. up to 70% material efficiency with STILFOLD .

- 70% component reduction and 40% lighter parts are validated in pilots

- Sheet layout optimization reduces offcuts to a fraction of the original.

The gains are clear: Adaptable assemblies, faster iteration, and a leaner, more sustainable manufacturing process, achieved in a real-world industrial setting.

Why this was needed in 2025

The broader manufacturing landscape is shifting towards:

- Sustainable manufacturing design: less waste, longer product lifespans.

- AI-driven geometric design: automating complex shape generation.

- Digital transformation in manufacturing: integrating design and production into one seamless flow.

Curve folding algorithms fit perfectly at the intersection of these trends. Bridging the gap between designer and folded creation. Taking something from a set of mathematical rules and turning it into a robust industrial process is what computational design enables.

Key Takeaways for Busy Readers

- Curve folding algorithms help design complex forms with simple design instructions to be made from flat sheets with fewer parts and less waste.

- Parametric design solutions make design changes faster, easier, and less error-prone.

- Different design scenarios and variations cost next to no time to iterate on.

- Sustainable manufacturing design benefits directly from optimized material use and reduced transport weight.

Whether you’re designing electric vehicles, furniture, or architectural components, the potential for delving deep into algorithmic design to the next level of your products and solutions is significant.

Let’s explore how your team could cut design complexity, streamline fabrication, and unlock new forms through computational geometry methods, just as we did for STILRIDE.

Ready to explore parametric workflows for your next project? Let’s talk. Also check out our latest carousel on linkedin!

Book a free 30-minute call with us to discuss your project:

Schedule here on Calendly

https://calendly.com/kane-borgmarkkula/30min?month=2025-10