Concrete Prefab is Getting Its AI Moment. Are You Ready?

The concrete prefabrication industry is undergoing a seismic shift as artificial intelligence (AI) and parametric workflows redefine how we design, produce, and assemble building components. For manufacturers willing to embrace this transformation, the payoff is immense: 30% faster production timelines, 20-30% material savings, and 50% fewer defects in prefab elements. Here’s how AI-powered digital fabrication is rewriting the rules of concrete prefab and why adopting a fully parametrizable workflow is no longer optional for staying competitive.

The AI-Driven Parametric Workflow: A Game Changer

At the heart of this revolution is the fusion of parametric design and AI optimization, creating workflows that adapt to project-specific needs while maintaining industrial efficiency.

Parametric Design: Beyond Static Templates

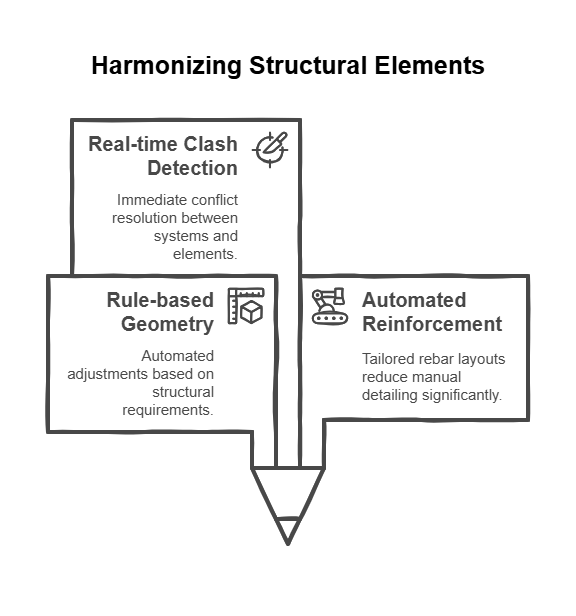

Traditional prefab relied on rigid templates, but modern tools like ALLPLAN Precast and Tekla Structures enable dynamic modeling:

- Rule-based geometry: Define relationships between elements (e.g., wall thickness adjusts automatically based on load requirements).

- Automated reinforcement: Generate rebar layouts tailored to plant capabilities, reducing manual detailing by 80%.

- Real-time clash detection: Resolve conflicts between MEP systems and structural elements during design.

For example, a parametric workflow can automatically adjust floor slab divisions based on trucking constraints, ensuring producible sizes without manual recalculation.

AI-Optimized Production: From Mix Design to Curing

AI is infiltrating every stage of prefab production:

Stage | AI Application | Impact |

Mix Design | Tools like Concrete Copilot generate 1,000s of mix variants in seconds, balancing cost and carbon footprint. | 30% CO₂ reduction, 12% savings. |

Formwork | CNC routers + AI nesting software cut material waste by 15%. | Faster formwork kits, less offcuts. |

Curing | Predictive models monitor temperature/humidity to prevent cracks. | 40% fewer curing defects. |

Digital Twins: Bridging Design and Assembly

AI-powered digital twins are transforming concrete prefabrication by eliminating costly on-site surprises. They enable real-time tracking of prefabricated elements, allowing teams to monitor production status and logistics with pinpoint accuracy. Through installation simulations, teams can test lifting sequences virtually, helping to avoid crane conflicts and site delays. For quality assurance, digital twins compare 3D scans of finished elements against the original BIM models, automatically flagging any deviations greater than 2mm, ensuring that what’s delivered matches what was designed.

Why Traditional Prefab Can’t Compete

Legacy workflows in concrete prefabrication often fall short due to three major issues. The first is rigid design, static CAD models can’t handle last-minute client changes without triggering weeks of rework. In contrast, parametric tools automatically update all related drawings and specifications, saving time and reducing errors.

The second issue is a lack of visibility in production. Without AI-powered analytics, manufacturers miss opportunities to optimize batch scheduling and reuse materials more efficiently.

Lastly, there’s the problem of fragmented data. Disconnected software systems often lead to mistakes in shop drawings and project delays. Tools like RIB One Prefab solve this by integrating BIM, ERP, and factory systems into one seamless workflow, enabling smoother operations from design to delivery.

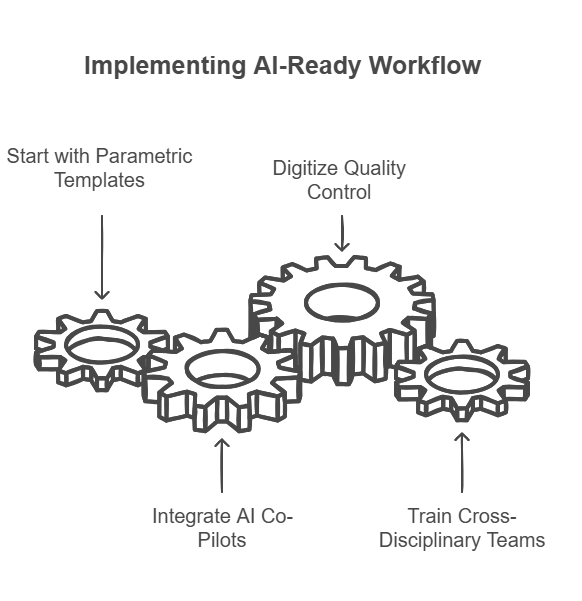

Implementing Your AI-Ready Workflow: 4 Steps

- Start with Parametric Templates

Build a library of smart components (e.g., walls with embedded conduit paths) to slash design time. - Integrate AI Co-Pilots

Adopt tools like Concrete Copilot for mix optimization or KI4PRECAST for curing predictions. - Digitize Quality Control

Use computer vision to inspect elements during casting, catching voids or misaligned rebar instantly. - Train Cross-Disciplinary Teams

Upskill detailers in algorithmic design and production managers in AI analytics.

The Future is Automated (and Profitable)

By 2027, 70% of prefab factories will use AI-driven workflows to:

- Print complex geometries on-site with adaptive 3D printers.

- Self-optimize production lines using real-time sensor data.

- Recycle 95% of formwork through parametric reuse algorithms.

Are You Ready?

The AI revolution in concrete prefab isn’t coming, it’s here. Manufacturers who delay adopting parametrizable workflows risk being outpaced by competitors leveraging 15-20% lower costs and 50% shorter lead times. The question isn’t whether to invest in AI, but how quickly you can turn it into a profit multiplier.

Start small: Pilot parametric wall design this quarter. Scale fast: Full workflow integration within 18 months. The first movers are already pouring profits.