The Science Behind Buildable Beauty

Could complex, stunning designs also be simple and sustainable to build? This isn’t just a futuristic concept; it’s the core promise of digital fabrication. At its heart lies geometry rationalization, the clever science of transforming intricate digital forms into components that machines can easily understand and construct. It’s the essential bridge between an architect’s vision and a physically buildable reality, driving both efficiency and environmental responsibility.

Geometry Rationalization: Making the Complex Buildable

Imagine designing a swooping, curved roof or a complex, organic-shaped light fixture. While breathtaking on a screen, translating that into actual panels or components that can be cut and assembled without immense waste or cost is a huge challenge. Geometry rationalization is the process of simplifying these complex forms into buildable components, often using repetitive, flat, or singly-curved elements, without losing the original design’s aesthetic intent.

Think of it this way:

- It’s like breaking down a tricky Lego model. Instead of one giant, impossible piece, you figure out how to build it with standard bricks.

- Or a tailor laying out fabric. You want to cut the dress pattern in a way that uses the least amount of material but still creates the perfect shape.

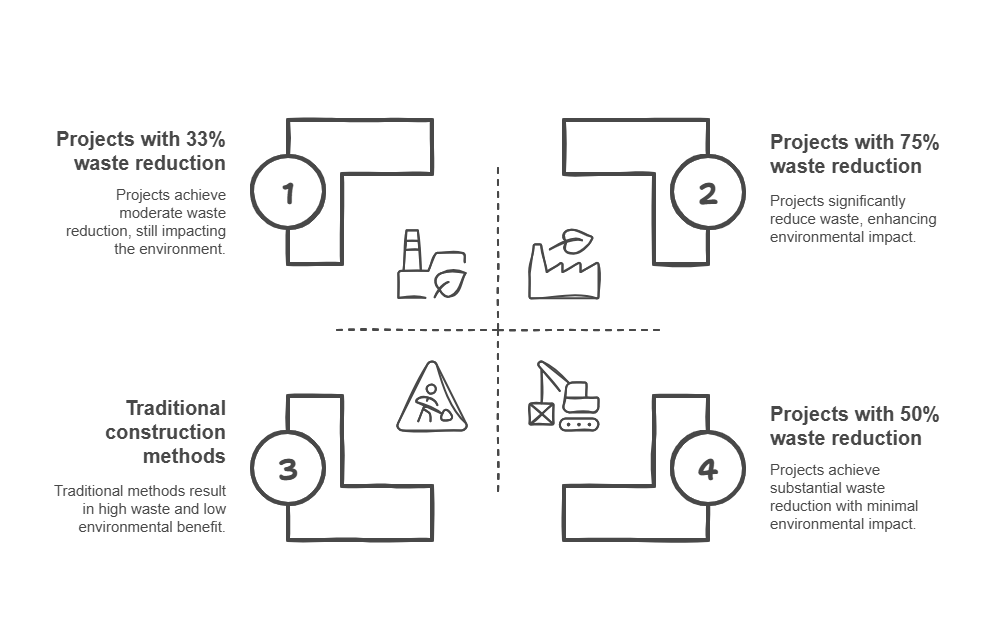

This isn’t just about making things cheaper or easier; it’s deeply tied to sustainability, reducing material waste, and allowing for faster, more precise construction. Studies show that design decisions can influence up to 33% of construction waste, making geometry rationalization a powerful tool for environmental impact. Some projects incorporating these methods have reported waste reductions of up to 75% compared to traditional construction.

From Concept to CNC: Real-World Examples

How does this complex process actually work? Let’s look at a couple of scenarios where digital fabrication, driven by smart geometry, makes all the difference.

Case Study: The Fluid Forms of Evolumination Lighting

Consider a design like Evolumination’s intricate lighting fixtures. These often feature complex, flowing curves and organic shapes. Manually trying to map out how to cut flat pieces of material that would assemble into such a form would be a nightmare, if not impossible, leading to massive waste and high labor costs.

Here’s how digital fabrication and geometry rationalization step in:

- The initial artistic concept is created digitally.

- Specialized software then analyzes the complex design.

- It then “rationalizes” this design, figuring out how to precisely slice it into a series of flat or subtly curved panels. These panels are carefully unrolled or flattened so they can be cut from standard sheet materials (like metal or wood) with minimal waste.

- These precisely cut components are then easily bent and assembled, creating the illusion of a seamless, complex form from simpler, buildable pieces.

This isn’t just theory; it’s how beautiful, seemingly impossible designs move from concept to the cutting edge of a machine. This precise fabrication often leads to cost reductions of up to 35% on certain projects and significantly faster production times, sometimes cutting weeks or months off traditional schedules.

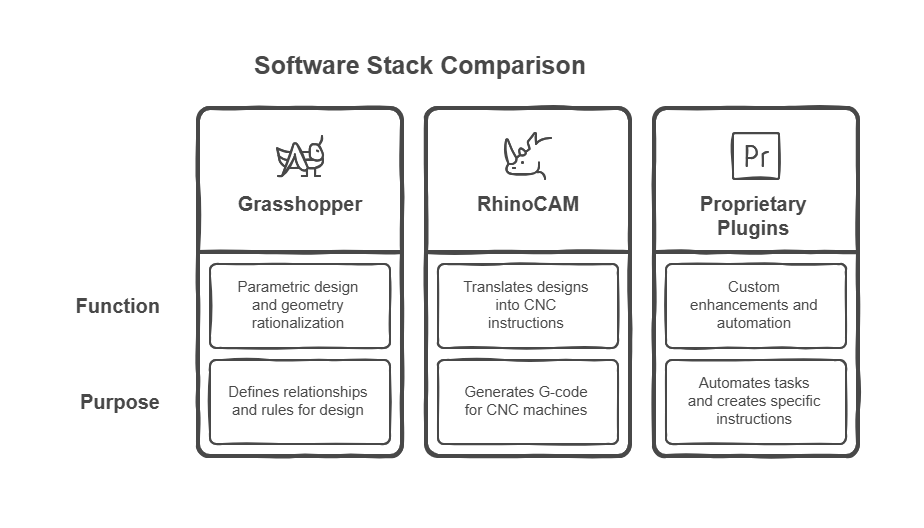

The Digital Architect’s Toolkit: Our Software Stack

Achieving this buildable beauty relies on a powerful combination of software. At the core, we’re talking about parametric design tools that allow designers to define relationships and rules, rather than just fixed shapes. This means when you change one parameter, the entire design intelligently updates.

Our typical toolkit for this includes:

- Grasshopper: A visual programming environment within Rhino 3D. This is where the magic of parametric design and geometry rationalization often begins. Designers build “definitions” (think of them as logical flowcharts) that describe how a complex surface should be panelized, unrolled, or broken down into flat components.

- RhinoCAM: Once the geometry is rationalized, RhinoCAM translates these simplified digital parts into instructions (G-code) that CNC machines can understand. It tells the machine exactly where to cut, drill, or carve.

- Proprietary Plugins: Often, off-the-shelf software needs custom enhancements. Specialized plugins developed in-house can tackle unique rationalization challenges, automate repetitive tasks, or create specific fabrication instructions tailored to a project’s needs.

This integrated software stack allows for unparalleled precision, material efficiency, and the ability to fabricate designs that were previously too complex or expensive.

What’s Next? The Future of Buildable Beauty

The field of digital fabrication is always evolving, pushing the boundaries of what’s possible. We’re on the cusp of even more exciting advancements:

- AI-Driven Mesh Optimization: Imagine AI algorithms that can automatically analyze a complex 3D mesh (a digital model composed of many small polygons) and instantly suggest the most efficient ways to panelize it for fabrication, further reducing waste and optimizing build time. This could take geometry rationalization to a whole new level of speed and efficiency.

- Biodegradable and Smart Materials: The focus on sustainability will only intensify. We’ll see digital fabrication processes tailored to work with cutting-edge biodegradable materials, minimizing environmental impact. For instance, some projects are exploring 3D printing with mycelium (fungal root networks) or recycled plastic and mineral waste, offering fully recyclable and lower-carbon alternatives. Smart materials, responsive to light, temperature, or pressure, will also be integrated, leading to dynamic, adaptive structures.

The journey from complex ideas to buildable realities is becoming more seamless, intelligent, and sustainable than ever before. Digital fabrication, powered by the continuous evolution of geometry rationalization and advanced software, is truly shaping the future of design and construction, making beautiful, complex forms not just possible, but buildable.

Ready to Turn Complex Designs into Buildable Reality?

Let’s explore how digital fabrication and geometry rationalization can transform your workflow, reduce waste, and bring your most ambitious projects to life, beautifully and sustainably.

Book a free 30-minute call with us to discuss your project:

Schedule here on Calendly