For years, online configurators were treated like interactive showrooms, nice to look at, fun to explore, but limited to surface-level customization. That era is over.

Today’s configurators don’t just help customers choose. They help companies design, price, and build in a single continuous digital flow. They’re no longer just visualization tools.

They’re the nervous system of modern manufacturing.

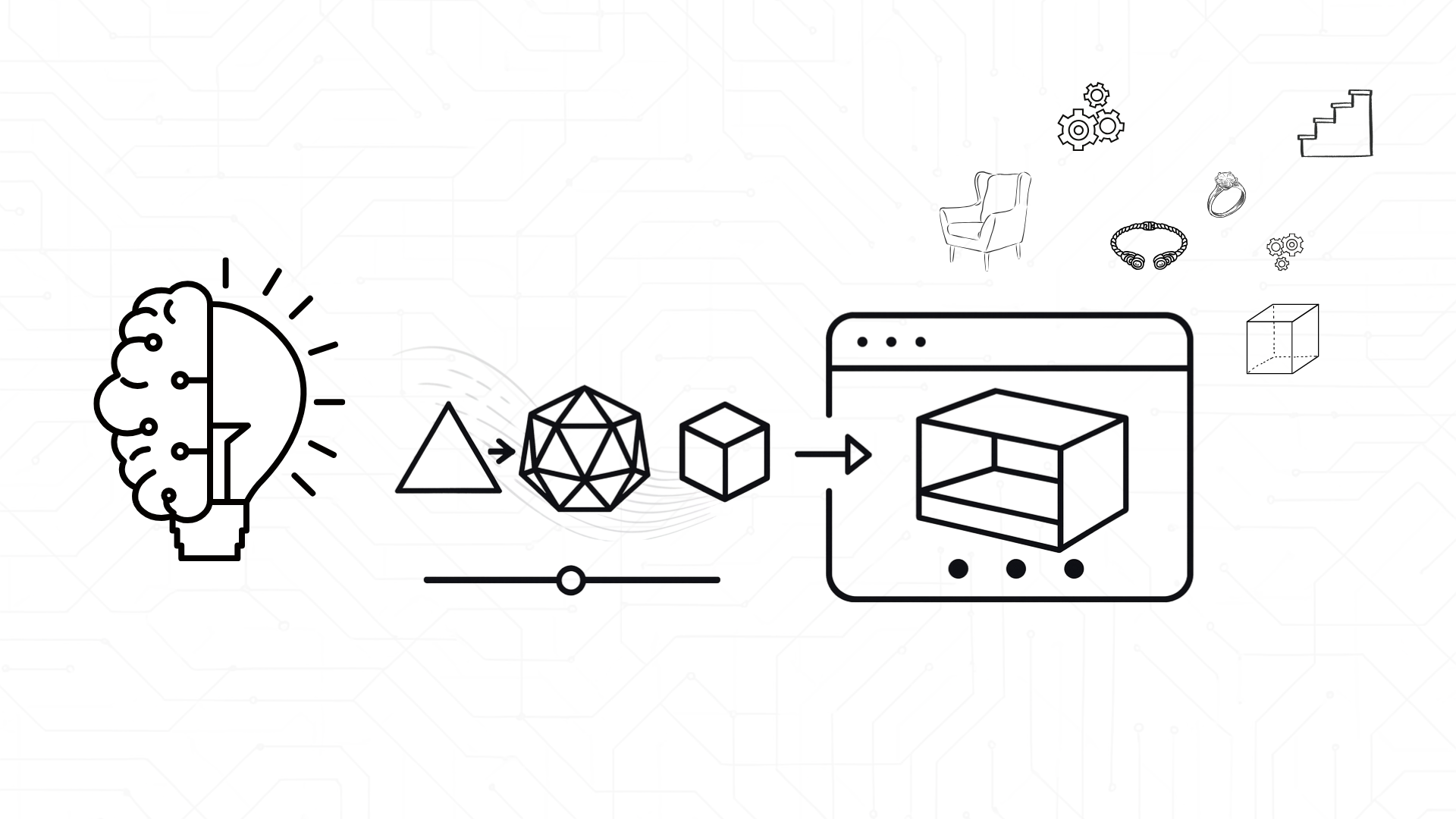

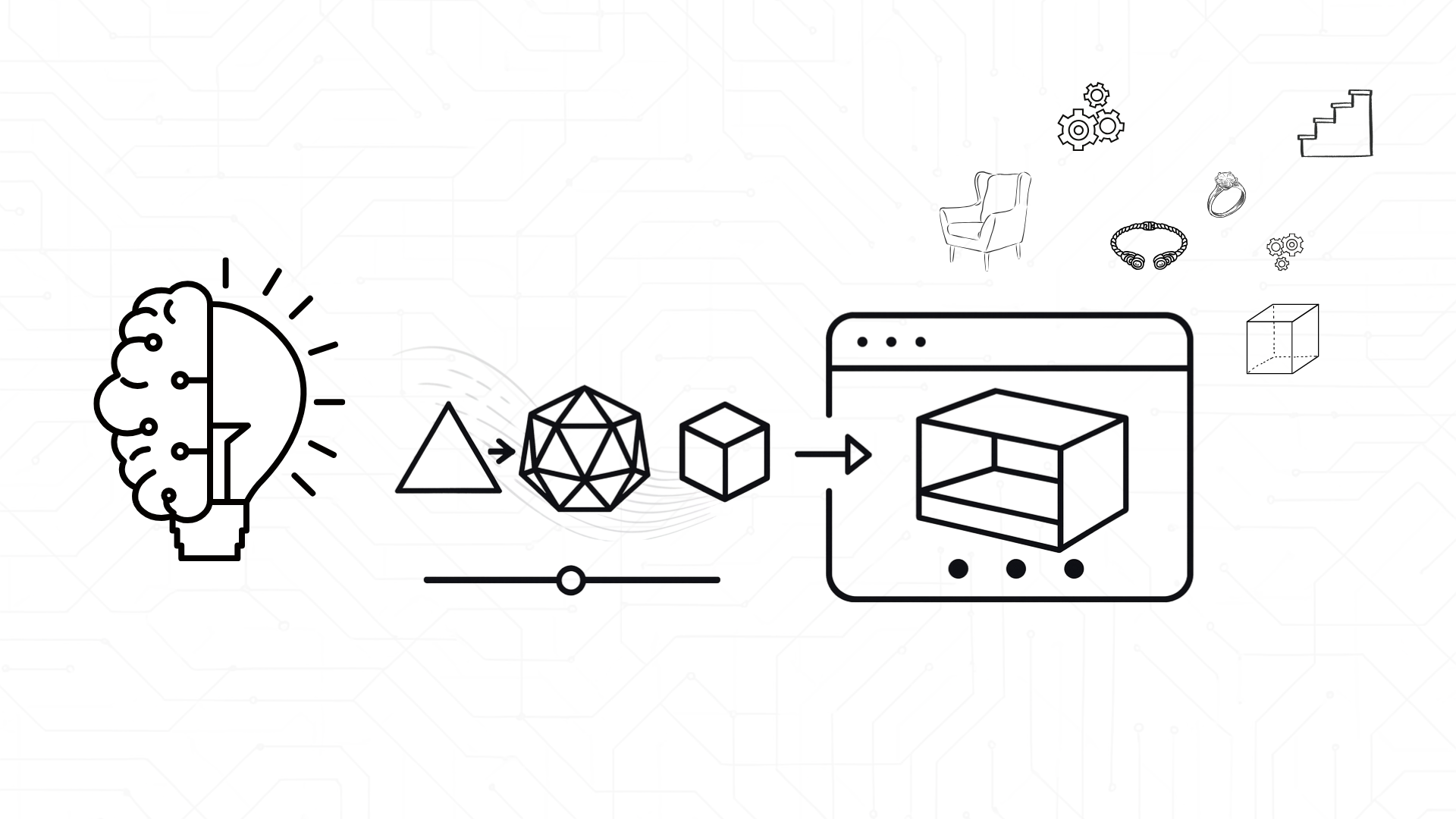

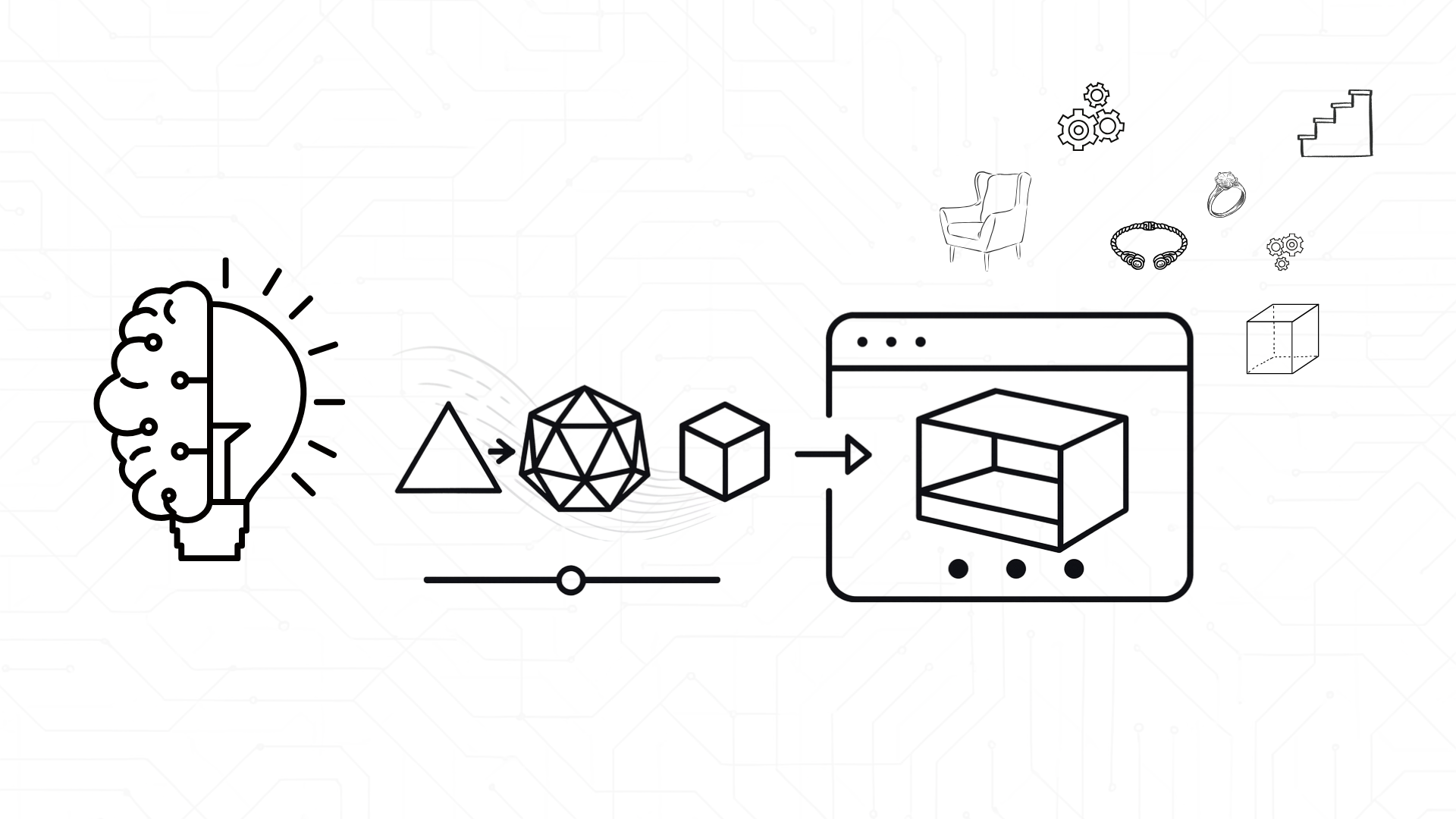

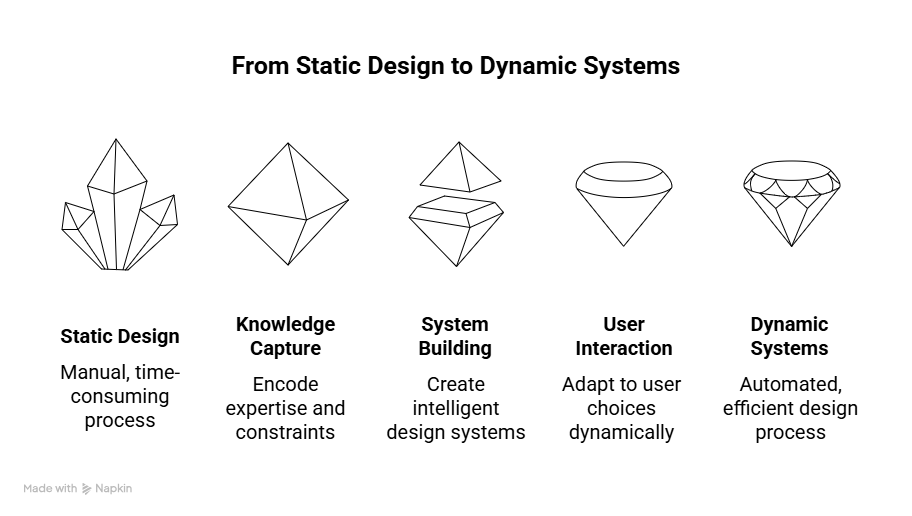

Configurators have evolved from simple 3D viewers into connected production systems.

Every time a user customizes a product, a series of automated rules can instantly:

That’s not visualization, it’s real-time digital manufacturing.

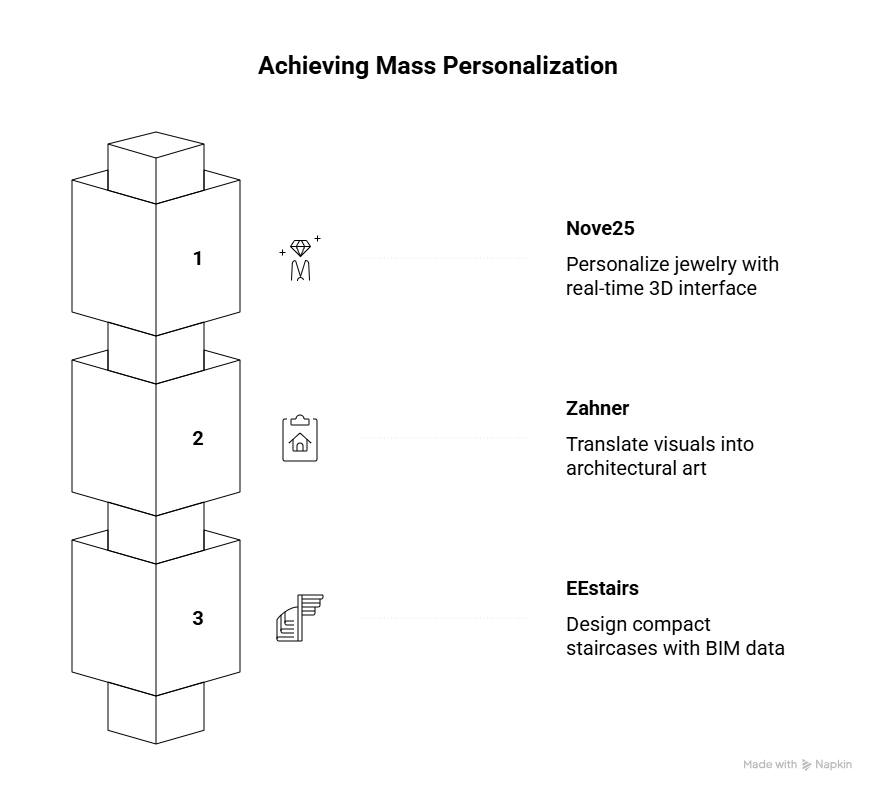

Three different industries.

One shared principle: configuration turns creativity into manufacturable precision

What makes these configurators powerful isn’t the 3D view, it’s the parametric logic that drives them.

They’re built on design systems that understand:

Platforms like ShapeDiver, Rhino Compute, and DriveWorks turn these design rules into living systems. When customers interact, they’re not just choosing, they’re co-creating within a structured, manufacturable framework.

Configurators mark a paradigm shift in how design teams work. Instead of producing static outputs, designers now build systems that design for them, systems that capture their knowledge, constraints, and craft.

Every new configuration becomes a reflection of encoded expertise, a living design that adapts intelligently to each user’s choices.

It’s not replacing creativity, it’s amplifying it, turning tacit knowledge into tangible systems.

The digital thread between e-commerce, engineering, and fabrication is tightening.

A single configurator can now handle the entire journey, from interactive visualization to real-time quoting, CAD generation, and production execution.

The result is a world where every product can be unique, yet the process remains predictable, efficient, and connected.

A client visits your site, tweaks a product’s dimensions, explores finishes, and instantly sees how it will look and how much it costs.

Moments later, your production line already has the right files and material data ready to go.

No middlemen. No re-drawings. No friction. Just seamless intelligence from design intent to fabrication reality.

That’s the world Borg Markkula is helping shape

where computational design meets digital craftsmanship,

and where configurators become the bridge between imagination and production.

At Borg Markkula, we help forward-thinking companies turn their design systems into living configurators, blending creativity, precision, and automation into one intelligent ecosystem.

Because the future of digital fabrication isn’t about showing more.

It’s about building smarter, together.