Beyond Options: Rethinking Customization Through Parametric Logic

Customization used to mean choosing from a set of options like colors, sizes, finishes, or modules neatly listed in a configurator. But that version of “choice” has started to feel limiting. Real customization isn’t about picking from what already exists. It’s about shaping what’s possible.

Across architecture, engineering, and manufacturing, a quiet revolution is unfolding. Designers are no longer drawing fixed forms; they’re building systems that can think. These systems understand the strength a structure needs, the performance a component must deliver, the efficiency a material can provide and generate geometry that satisfies those goals.

This shift defines the rise of Parametric customization: where products aren’t designed through repetition, but through reasoning. It’s a move from selecting options to computing outcomes, powered by modular parametrization and real-time intelligence.

What was once a linear process of design, review, and fabrication is now becoming a continuous feedback loop, where each decision informs the next, and each model learns from its logic.

What Parametric customization Actually Means

Traditional configurators simply display menus of options. In contrast, parametric systems understand why something must be designed a certain way. They interpret performance intent such as strength, efficiency, or environmental criteria and generate geometry that satisfies those conditions.

Every input drives a live computational model that adjusts dimensions, materials, and logic in real time. The result is an intelligent interface where outcomes emerge from reasoning, not repetition.

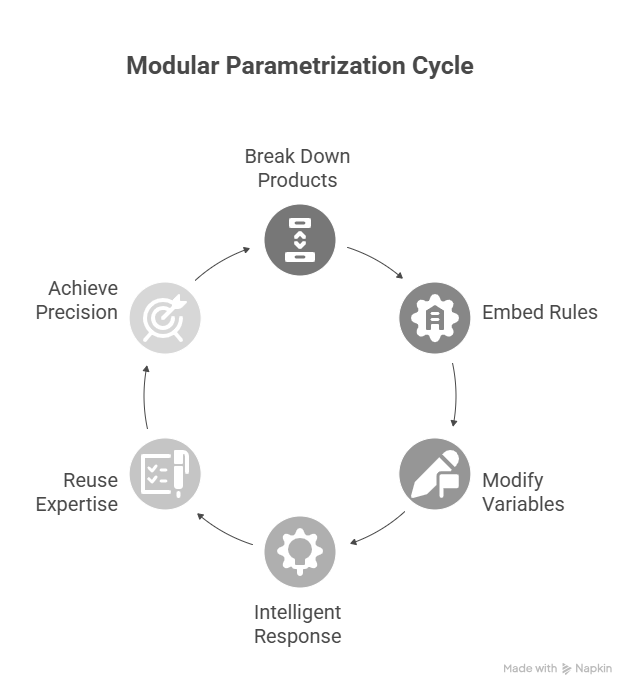

The Role of Modular Parametrization

Modular parametrization breaks complex products into interdependent, reusable components. Each module carries embedded rules and relationships, ensuring that when one variable changes, every connected element responds intelligently.

This approach captures expertise once and reuses it across multiple designs. It delivers consistent outputs, faster iteration cycles, and traceable design logic. Designers can modify intent instead of redrawing geometry, achieving precision and efficiency simultaneously.

When Configuration Becomes Fabrication

Parametric customization acts like a fabrication engine inside a design tool. Every change validates constraints, updates geometry, and produces manufacturable outputs, often ready for CNC or BIM workflows.

There are no redraws or manual conversions. The transparent workflow connects design intent with production logic, ensuring accuracy, speed, and repeatability at any scale.

The Business Value of Intelligent Configurators

Intelligent online configurators do far more than enhance user engagement. They streamline design-to-production workflows, reduce quoting time, and minimize rework. Teams that adopt this approach consistently see faster decisions, lower uncertainty, and stronger collaboration across design and manufacturing.

While the metrics vary by sector, the pattern is clear: automation anchored in parametric reasoning drives measurable improvements in productivity, reliability, and customer confidence.

The Technology Behind Advanced Configurators

Behind every modern configurator lies a three-layer digital ecosystem. The computational logic layer defines rules, relationships, and performance parameters. The web interface layer translates these into intuitive, browser-based interactions. Finally, the production layer converts validated results into fabrication files or BIM data for downstream workflows.

Together, these layers form a unified parametric stack. Each communicates continuously with the others, keeping design, engineering, and production perfectly aligned without duplication or data loss.

How Parametric customization “Thinks”

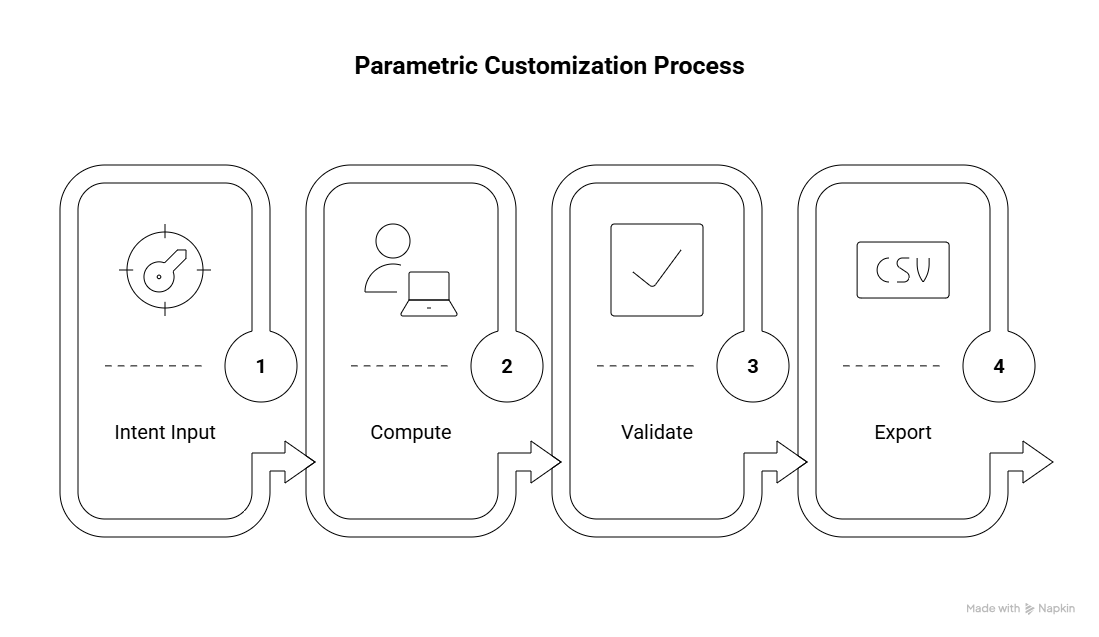

Under the hood, every session follows a consistent loop:

- Intent in

Inputs capture performance goals, envelope, materials, and rules that must hold true. - Compute

The engine resolves constraints, updates geometry, and estimates key metrics needed for approval. - Validate

Design checks confirm structural, spatial, and fabrication requirements before anything is exported. - Export

Approved variants generate standardized files for production and documentation.

Applications Across Architecture and Manufacturing

From modular housing and façade systems to furniture, mechanical components, and digital fabrication workflows, Parametric configurators are redefining how ideas become physical.

Architects and engineers use them to automate compliance and generate design variants, while manufacturers rely on them to produce accurate toolpaths and empower clients to co-create safely within defined limits. The bridge between imagination and production is now computational.

Why Forward-Looking Firms Are Adopting It Now

Parametric configurators convert design expertise into reusable intelligence. Each project adds to a growing library of tested rules and performance data, allowing teams to evolve continuously.

A well-structured configurator becomes a living design system, one that is readable, scalable, and adaptable across teams, disciplines, and tools. For firms seeking digital continuity, this marks a practical step toward fully connected, automation-ready workflows.

Building Smarter, Not Just Faster

The future of design is adaptive, data-driven, and deeply interconnected. When systems can explain their logic, both people and machines trust the outcome.

At Borg Markkula, we build Parametric Configurators that merge creativity with computation, transforming configuration into fabrication.

Ready to explore the next generation of design automation?

let’s connect! to learn how modular parametrization can power your next project.

https://calendly.com/kane-borgmarkkula/30minhttps://